Tel: +86-17717557262 Email: shsaikun@gmail.com

Wilden® AODD pumps are classified as reciprocating, positive-displacement-style pumps. The pump operates by displacing fluid from one of its two liquid chambers upon each stroke completion. To operate correctly, AODD pumps require a precise amount of pressure (measured in pounds per square inch) and air (measured in cubic feet per minute) to deliver the proper amount of fluid.

The simple genius of the Wilden AODD pump design means that there are only a few wetted parts that are dynamic: the two diaphragms, which are connected by a common shaft, the two inlet valve balls and the two outlet valve balls. The diaphragms act as a separation membrane between the compressed air supply and the liquid. Driving the diaphragms with compressed air instead of the shaft balances the load on the diaphragm, which removes mechanical stress from the operation and extends diaphragm life. This also allows the valve balls to open and close on the valve seats, which direct liquid flow. This simple design and operation makes it easy for the operator to find the correct pressures and flows to optimize its operation.

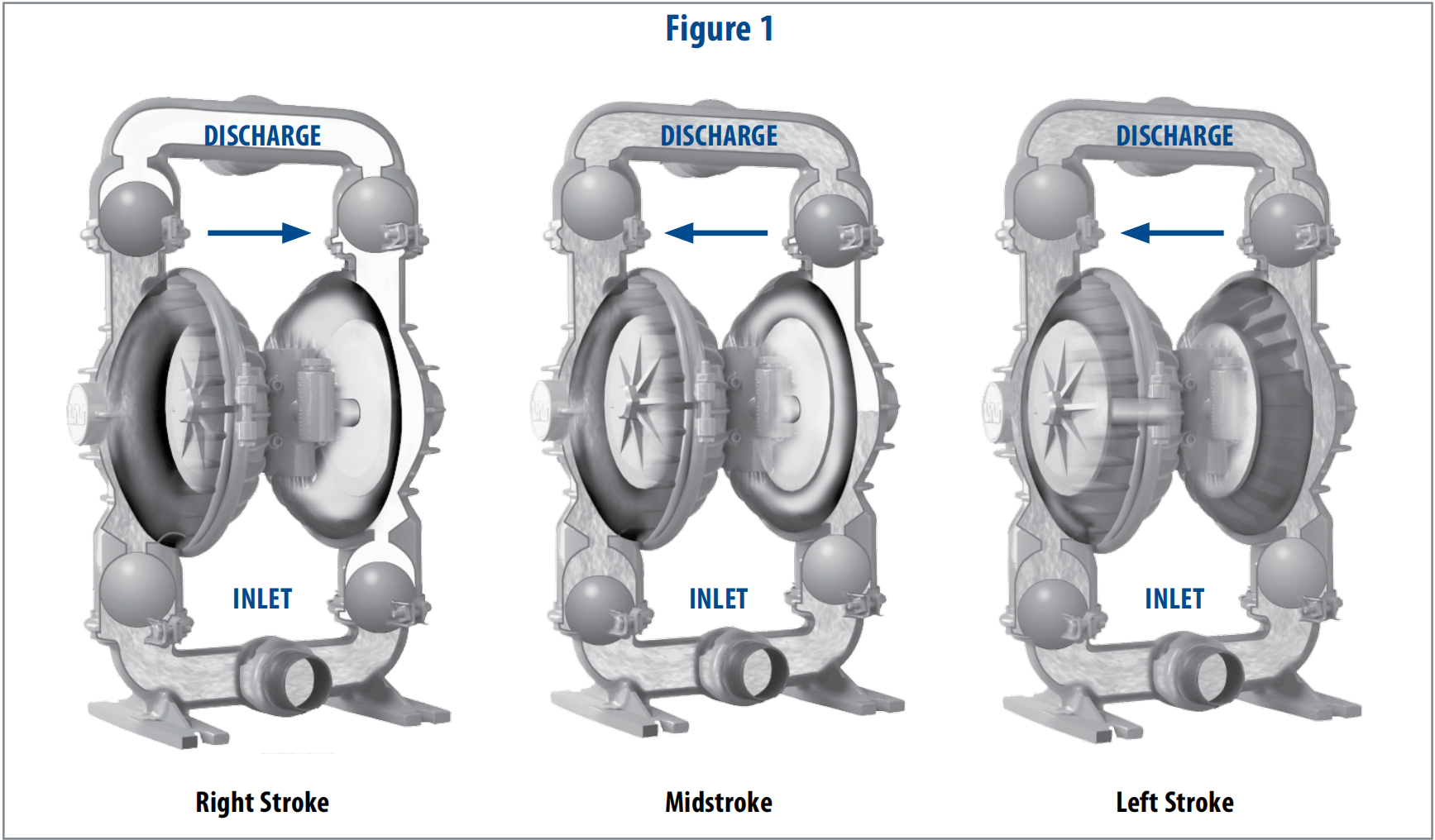

More specifically, the pump begins operation when the air distribution system directs the air supply to the right air chamber and back side of the diaphragm (See Figure 1). This moves the diaphragm away from the center block and toward the liquid chamber, in the process pulling the opposite diaphragm inward. This means the opposite diaphragm is now on its suction stroke. At the same time, atmospheric pressure forces fluid into the inlet manifold, forcing the inlet valve ball off its seat. This allows liquid to move past the inlet valve ball and into the liquid chamber.

When the pressurized right liquid chamber reaches its liquid capacity, the air valve redirects compressed air to the back side of the opposite diaphragm. This forces that diaphragm away from the center block while pulling the right diaphragm toward the center block. This closes the inlet valve ball on the opposite side while lifting the discharge valve ball off its seat and forcing the liquid to flow through the discharge manifold. The process is repeated for the opposite side, with the liquid chamber filling, the forced air redirecting the diaphragms and the created pressure forcing the discharge valve ball off its seat as the liquid moves through the discharge manifold.

As the pump reaches its original starting point, each diaphragm has gone through one suction and one discharge stroke, which constitutes one pumping cycle.

About the working principle of Wilden AODD pump

1955 by Jim Wilden when he revolutionized the

New Product Release ,Almatec,E2.0

Contact: Amy

Phone: +86-17717557262

Tel: +86-17717557262

Email: shsaikun@gmail.com

Add: No. 133, Dongzheng Village, Lingang New Area, China (Shanghai) Pilot Free Trade Zone